Back Pressure Effects on Relief Valves

The back pressure at production train can affect the relief valve’s capacity or the relief valve’s set pressure. The capacity of a relief valve is the maximum flow rate while the set pressure is the cranking pressure of the relief valve. On conventional relief valve, the set pressure increases directly with back-pressure. The pressure set can be lowered to compensate a constant back pressure on conventional relief valve. The relief valve which relieving into the production header is causing fluctuate back pressure. The maximum back pressure on conventional relief valve is limited to 10% due to the effect of back-pressure on the set point.

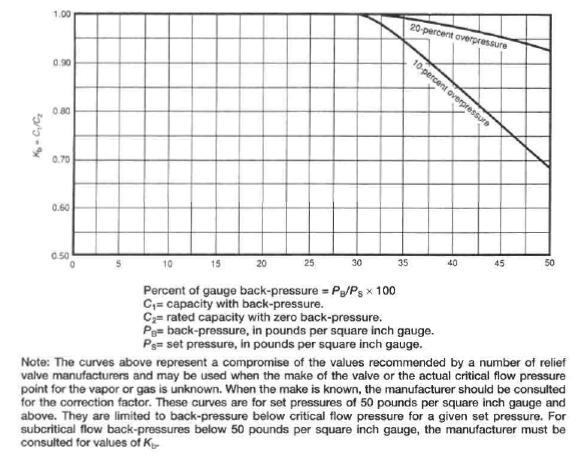

The set points for pilot-operated and balanced-bellows relief valves are unaffected by back-pressure, so they are able to tolerate higher back pressure than conventional valves. Those valves will have a capacity decreasing if the back-pressure goes above a certain limit.

The 35% back pressure can affects the stiffness of the bellows and decreases the relief valve’s capacity on balanced-bellows relief valves. To achieve the proper capacity, the relief valve can be resizing into higher size.

The back pressure starts to affect the relief valve at 50% of set pressure in which the relief valve is reaching critical flow. Pilot operated relief valves can handle up to 50% back-pressure without any significant effect on valve capacity. API RP 520 gives a generic method for pilot-operated relief valve sizing.

The limitation for relief valve back pressure can be summarized as.

The relief piping design pressure is an additional limit to back-pressure. Relief piping is usually designed as ANSI 150 piping with a MAWP of 285 psig. Relief valves with ANSI 600 inlets usually have outlet flanges rated ANSI 150. A pilot-operated relief valve set at 1,480 psig could have a back-pressure of 740 psig without affecting the valve’s capacity, but that would overpressure the relief piping so the allowable back-pressure is limited to 285 psig. For this reason, ANSI 900 and above relief valves often have ANSI 300 outlet flanges to allow for higher back-pressure in the relief piping.

Categories: Pressure Relief | Tags: balanced-bellows relief, conventional relief valve | Leave a comment