Welding Preheating

Preheating is the process of raising the temperature of the base metal above ambient temperature immediately before welding and holding it during welding. Preheating is not recommended for austenitic stainless steels. However, for carbon and alloy steels it is extremely important. Preheating carbon and alloy steels accomplishes the following functions:

• Reduces residual stresses, shrinkage, and distortion by minimizing differential thermal expansion between the weld metal and base metal. This is especially important for welds on thick sections or welds with high restraint.

• Reduces weld metal and heat affected zone (HAZ) hardness by slowing down the cooling rate. The driving temperature gradient between the molten weld metal and base metal, as well as the thermal conductivity of the base metal, is reduced by preheat. See Figure 600-20.

• Increases the diffusion rate of hydrogen from the weld metal and HAZ. This helps prevent hydrogen embrittlement cracking (also called underbead cracking or delayed hydrogen cracking) of the weldment when it cools to ambient temperature.

Minimum preheat temperatures for carbon and alloy steels are primarily determined by:

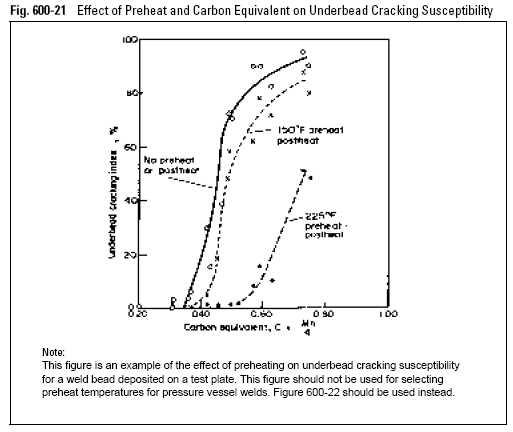

The hardenability of the weld metal and HAZ. This is determined by a calculated “carbon equivalent (CE)” factor. Basically, the greater the CE, the greater the required preheat. See Section 140 of the Welding Manual for more information on CE and how it affects preheat. See Figure 600-21 for the effect of hardenability (or CE) and preheat on underbead cracking susceptibility.

The amount of restraint in the weldment. For pressure vessels, this is primarily dependent on metal thickness.

The hydrogen charging characteristics of the fluxes or electrodes. This is not usually a consideration if low hydrogen electrodes or fluxes are used. If non-low hydrogen fluxes or electrodes are required for some reason, then the minimum required preheat should be increased appropriately. Consult a welding or materials engineer.

Minimum recommended preheat temperatures are summarized in Figure 600-22 for common pressure vessel materials. Note that these recommendations exceed the ASME Code minimum values for some materials. See Sections 100, 300, and Appendix A of the Welding Manual for other materials or for additional information on preheating.

Categories: Fabrication | Leave a comment