Function of Separation Operations in Refining

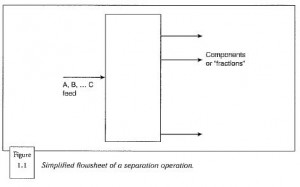

A crude oil is made up of a complex mixture of a very large number of components, most of which are hydrocarbons. In order to get petroleum products that meet given specifications, it is first necessary to separate out the different fractions or cuts, which then need to be purified or converted, especially when they are designed to be used by the petrochemical industry. The basic principle of a separation operation is illustrated in below.

The initial mixture (crude oil or any other mixture, A, B, C) is separated into different components or into different “fractions”, characterized by a distillation range for example. This type of operation generally requires an input of energy or of a selective separation agent, under conditions that will be dis¬cussed later.

More specifically in oil refining, separation processes have three main functions as defined below.

• Fractionation

Atmospheric distillation, which is designed to fractionate crude oil into different cuts such as liquefied petroleum gases, gasoline, lcerosine, diesel oil, fuel oil, etc., is a good example.

Additionally, most catalytic processes include a fractionation stage designed to yield products that will ultimately meet the desired specifications.

• Recycling

Most chemical transformations are characterized by incomplete conversion for a single pass through the reactor, and a separation stage is required to separate and recycle the non-converted components (Fig. 1.3).

For instance, the need to increase the octane number of gasoline stocks to produce unleaded gasoline means that normal C5 and C6paraffins have to be

isomerized. The normal paraffins that remain unconverted when they exit from the isomerization process are separated by adsorption on 5A molecular sieves and recycled to achieve complete isomerization.

• Purification

Certain toxic impurities that are detrimental to the environment or incompatible with the product’s end use can be eliminated by separation processes.

A purification stage may be necessary in anticipation of a later operation, for example a catalytic stage when the catalyst is sensitive to the impurities in the feed.

Lastly, some products must meet high purity requirements for later use in the petrochemical industry (paraxylene, for example).

Categories: Petroleum Refinery | Tags: hydrocarbons | Leave a comment