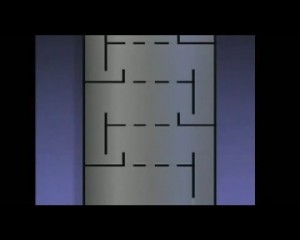

Distillation Tower Sections

Every distillation tower can be divided into three different sections. The middle section is where the feed enters the tower and part of the feed vaporized. This vaporization is commonly known as flashing, so this section of this tower is often called the flash zone. The section above the flash zone is the rectification section. At this part of the tower, the concentration of lighter components increases. The section of the tower below the flash zone is called the stripping section. In this section the lighter components are vaporize or striped from the heavier liquid.

The schematic above shows one type of distillation tower. This tower uses trays called sieve trays to separate vapor and liquid. The trays are spaced through the tower they’re called sieve tray because they have many opening in them like a sieve. The opening in the trays allow vapor to rise through the trays on their way up the tower. Each tray is also designed to hold liquid. Dams or weirs on each tray allow liquid to build up on the tray. Liquid that over flow the weirs flow in to downcomers, the downcomers channel the liquid from tray to tray down the tower. When the upward moving vapor and the downward moving liquid coming contact in each tray, the vapor transfers some of their heat to the liquid. Two things happened, the heavier component of the vapor become cooler and condense into liquid and the lighter component of the liquid boil. The vapor then rise toward the next tray as this process continues the rising vapor contains higher concentration of lighter components and lower concentration of heavier components.

Categories: Gas Processing | Tags: Distillation Tower, flash zone, rectification section, sieve trays, stripping section | Leave a comment